Last updated: 28 March 2004

|

Last updated: 28 March 2004 |

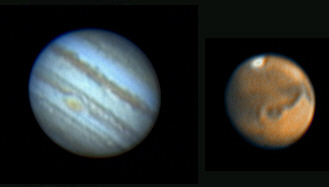

Date: 3/26/04, 14:13 From: Christoph Jansen (CJansen@uebersetzungsbuero-jansen.de) Sturdy polar wedge for the ETX 125 made of plywood I built my own polar wedge from plywood, which I bought as scrap in a DIY store. On using this wedge for the first time I found that it is perfectly stable. Now being able to use the "Scheiner" method for polar alignment, I enjoyed having mars in my 9.5 mm plossl eyepiece (about 200x magnification) for more than 4 hours without any correction.I can now place a planet or the moon in the field of my webcam and record AVIs without any correction, even using focal lengths of 6 m. This is far more than I hoped to achieve and it underlines the power of the ETX if one cares to give it the best operating conditions one can. Here are examples of Mars and Jupiter taken in this configuration:

Jupiter on Mar 26 2004 at 21:35 UT, f=4000 mm, 2x TeleVue Barlow, 680 of 740 images used; Mars on Sep 29 2003 at 21:52 UT, f = 5500 mm, eyepiece projection with 9,5 mm Meade 3000 plossl, 400 of 500 images used. Both images with ETX 125 and ToUCam Pro at 640x480 resolution, 10 frames/s, stacking and processing done with Registax 2.0. More pictures under: http:people.freenet.de/Astroseiten/ For anyone tring to make this kind of wedge himself and to whom the picture above is not sufficient to do so, here is a description of how I built it. I used: 1 base board, 20 cm x 38 cm, 15 mm thick 1 altitude board, 20 cm x 25 cm, 15 mm thick 2 (identical) arms of the same thickness as the boards with an empty space for the bolts, max (outer) radius is about 20 cm 2 threads to be screwed into the base board (the tripod adapter is fixed to the board with these threads) 2 threaded bolts to be screwed into the sides of the base plate; one end with a thread for the knobs below and the other end with a thread for wood 2 knobs fitting on the threads of the two bolts, used to fix the altitude setting 2 steel washers fitting under the knobs 1 hinge 10 cm x 2,5 cm (4 inch x 1 inch) 8 screws to fix the hinge 4 screws and 4 wooden dowels with 4 mm diameter to fix the arms to the altitude board 2 screws for screwing the ETX to the alt board, in my case 1/4 inch in diameter and 1.25 inch in length; this may vary with the plywood's strength 2 screws for fixing the tripod adapter to the base board 2 steel washers fitting under the above screws' heads Further needed: wood glue, paint, two spare nuts fitting the threaded bolts The overall cost for the material was about 20 Euros. As I had no wood, none of the screws, no dowels and no glue, I had to buy all of this. So you may find a lot of the needed accessories in your stock which makes it a lot cheaper, probably lowering costs to virtually nil. This kind of wedge can of course easily be used for all other ETX's, you may just have to adjust the sizes of the material used. Cut the boards to size and construct the arms. For the arms you only need a pair of compasses. My arms have an inner radius of 15 cm and are 5 cm wide, giving an outer radius of 20 cm. The empty space has a center radius of 17,5 cm and is 1 cm wide, so radii of 17 and 18 cm are used to draw it. The arms cover about 65 degrees, which is sufficient for latitudes of up to 25 degrees. To cut out the empty space in the arms, I started by making a cut in the middle of their top. As this part of the arms is later fixed with dowels and screws this doesn't affect stability. I drilled the holes to fit the threads for the adapter into the base board and then screwed the threads into them. The first hole is 10 cm from the back edge of the board, the second is 10,2 cm (4 inches) apart, but this may vary with the adapter used. Two holes to fit the screws that would later hold the ETX were drilled into the altitude board. As I don't know if changes were made to the ETX's base plate, one better measures the distance between the holes oneself. Now all wooden parts were painted leaving out the inner top of the two arms which was later glued to the altitude board. The hinge was now fixed to the base and altitude boards in that way, that their front edges are side by side. With the sizes I used for the boards, the hinge is now well over the middle of the tripod adapter. This is about where the center of gravity of the scope will later be, but this of course depends on the preferred observation point's latitude. At lower latitudes you may have to shift the hinge further to the base boards front for proper equilibrium. Now the arms were fitted to the sides of the altitude board, which is a bit tricky, at least if your are used to doing such constructions as little as I am. If you want to do this point straightforwardly, you have to embed the hinge into the wood. You may then simply construct the position of the arm from the used radii. Lacking the proper tools to do so, I just screwed the hinge on top of the boards, which causes an angle between them. This means that you can't just go ahead and fix the arms in the right place by measuring. So you have to do it by trial and error. Start out by marking a dot on the base board. Its position is given by using the radius of the arm's empty space measured from the hinge. Now hold the arm to the alt board in that way that the dot at the center of the empty space and move it up and down. If the dot on the base board does not stay inside the empty space, try setting another dot in a better position. This way I soon found the right position for the arms. Now mark the position of the arm on the alt board and at the last dot's position drill a hole into the side of the base board into which the threaded bold will be screwed. Mark the same positions of arm and hole on the other side of the boards and try if it fits as good as on the first side. If it doesn't (which was the case for me, I'm really not a good carpenter), correct it. Before continuing, take some sandpaper and remove the paint from the base board where the arms will be glued to it. Now drill four holes into each arm. Two of them are 1 mm wide for screws and will go right through the arms; the two others are 4 mm wide for the dowels and are only drilled into the arms' inner side, just deep enough to glue the dowels into them. Place the holes alternating by diameter: 1mm, 4 mm, 1 mm , 4mm. Drill the corresponding holes into the alt board. Now first glue the dowels into the arms, put some glue onto the arms' sides and into the holes for the dowels. Fix the arms to the board and screw them tight. Put two nuts on each of the threaded bolts, screw them tight against each other. Now you may use a wrench to screw the bolts into the base board (of course through the empty space of the arms, you won't be able to wrestle the arms over the bolts later). Remove the nuts and screw the knobs on the bolts. There you are, your wedge is finished. Before using it I painted it once more and roughly adjusted its altitude to my location which is round 53 north. As I said above, the increase in performance by now only having to track one axis (after careful alignment) amazed me and leaves me quite happy with this new accessory. I feel that now I really have the ETX I ever wanted. I hope this encourages some people to make their own wedges, it really is worth the effort. Regards, Christoph Jansen

Return to the top of this page.

Go back to the Tech Tips page.

Go back to the ETX Home Page.