Sent: Monday, October 19, 2009 01:56:07

From: infoforplt (infoforplt@comcast.net)

Thanks for the great website. A little history of my experience here is

necessary. I purchased an ETX 125EC used in early 2008. I spent the

Spring and Summer of 2008 familiarizing myself with the scope. I had

common problems that others had experienced and I was able to work

through them with information gleaned mostly from your website and a few

other sites. I overall had very few problems and had wonderful viewing

experiences. I live in Southern Minnesota (USA) and my scope had been

packed away pretty much since November 2008. I first took it out again

in April of this year. Well, the first night out I went through a reset,

calibrate motors, and train drives and then performed an Easy Align. I

slewed to the Moon and it tracked for a minute and then I heard a loud

pop and tracking in Azimuth was gone. The RA drive had failed. I

initially contacted Dr. Clay and he was unable to help as Meade didn't

stock or provide repair service for this model any more and he had no

parts available either. I contacted Meade and their response was (of

course) upgrade to a newer model ETX. I was considering saving some

money to purchase an LXD75 mount to replace the ETX fork mount. Well,

times being as they are I was unable to come up with enough money. After

spending the summer without my scope and missing many beautiful nights

of viewing the stars, I came up with a plan to repair the gearbox

assembly.

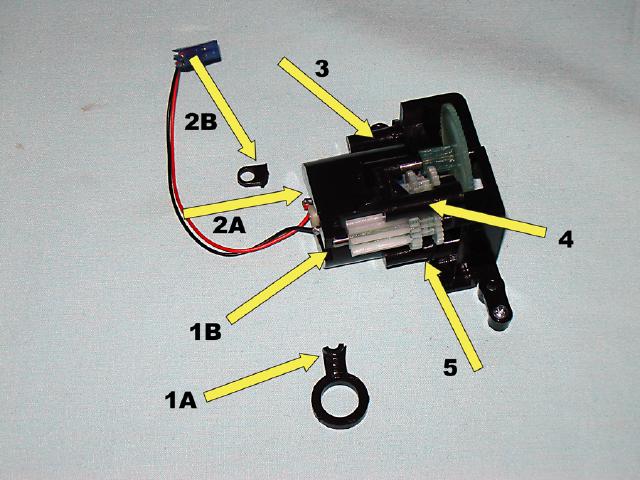

I have included a few photos that include the broken gearbox:

the partially repaired gearbox:

the partially repaired gearbox:

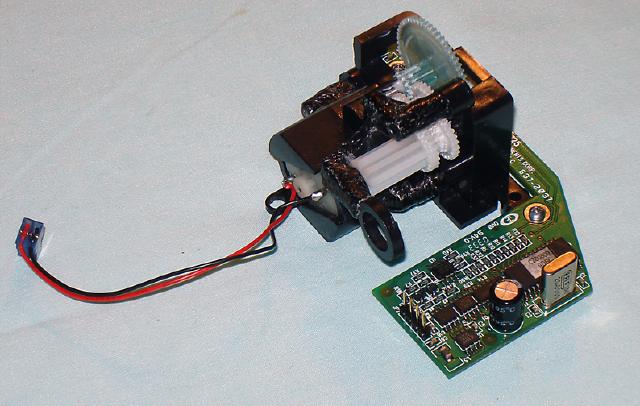

and the fully repaired gearbox ready for reinstallation into the base:

and the fully repaired gearbox ready for reinstallation into the base:

I've kept good notes with more photos of the supplies used and will at a

later date document the full procedure of the repair, though this is not

a repair for the faint of heart. I will try here to briefly describe

what I have done. I estimate cost of supplies at about $100.

I first used plastic pipe cement that I purchased from a local hardware

store to reattach the transfer gear support arm and mounting tab

(ETX125_01.jpg, arrows 1 & 2). I used a type that is good for ABS, PVC,

and CPVC plastic as I figured that the gearbox was made out of ABS. ABS

is commonly use for small plastic parts such as this. Turns out I must

have been right as ETX125_02.jpg shows the gearbox after the initial

repair. These repaired joints are very strong and I was tempted to test

it but I went a step further.

I then used carbon fiber woven cloth (and strand in a couple of areas)

and West System Epoxy to reinforce the support arm and also to reinforce

the gearbox cover screw supports as these had severe cracks in them.

These are numbered 3, 4, & 5 in photo ETX125_01.jpg. I couldn't come up

with a practical solution for reinforcing the mounting tab and if it

fails again I will fashion an L bracket to replace it with. The carbon

fiber I used was from a sample pack that I purchased online through a

company called Fibre Glast. The West System epoxy is commonly used in

marine craft fabrication/repair and is widely available.

ETX125_03.jpg shows the repaired gearbox ready for reinstallation. I

removed the circuit board prior to installation, as it is easier to

install the gearbox without it attached. I had to remove it again later

as I had applied too much Lithium grease, which had spattered about

after initial testing. I tested the scope indoors performing reset,

calibrate motors, and test tracking. After some necessary readjustment,

etc., which I will document in more detail later, I was ready for

outdoors testing.

I went out about 1:30am CST, Sunday morning here in Southern Minnesota.

I was greeted during setup with a couple of meteors from the approaching

Orionid meteor shower. I performed an extensive Train Drives starting

with my 26mm eyepiece, stepping down to 20mm, 15mm, 12.4mm, and 9.7mm. I

then performed an Easy Align.

I am very happy to report that the repairs appear to have been

successful. I spent about 2hr running through the Guided Tour (twice

for several of my favorites) of the Autostar without a hitch or error of

any kind. Tracking was excellent once an object was centered in the

eyepiece. Several times I let the ETX track and walked away for 5 10min

and when I came back the object was still centered in the eyepiece. I

also noticed that the growling, that used to be quite evident before the

failure when the RA drive was tracking, is greatly reduced. I will

perform more extensive tests if the skies stay clear this week, allowing

the scope to track for 15min and longer on a single object.

To sum it up, I think the repairs should hold up well. Only time will

tell. The carbon fiber reinforced areas of the gearbox will be stronger

than how it was initially molded. How the stresses will be transferred

to other areas of the gearbox I don't know. If I had to hazard a guess,

I would think the mounting tab or the support arm loop for the transfer

gear would fail first. The flexing in the support arm that caused the

initial failure is virtually nonexistent with the carbon fiber

reinforcement. I am hoping the repairs will hold at least another year

until I can save up for a new scope, after which I will use the ETX

primarily for terrestrial photography. After pricing the LXD75 mount,

tube rings, Sky Assurance, and other accessories necessary to mount the

ETX tube, I have decided to keep saving until I can purchase a new LXD75

SC8 full setup.

I'm hoping you'll post this on your site. It may also give others who

have had this failure something to think about before giving up on their

ETX 125EC. I have also sent a copy of this to Dr. Clay. Thanks for a

wonderful website. I peruse here from time to time and it has been fun

reading about your journey to Cassiopeia Observatory. Your website has

been an invaluable source of information about how to get the most out

of my ETX. Thank you.

Yours truly,

Paul Torgusen

I've kept good notes with more photos of the supplies used and will at a

later date document the full procedure of the repair, though this is not

a repair for the faint of heart. I will try here to briefly describe

what I have done. I estimate cost of supplies at about $100.

I first used plastic pipe cement that I purchased from a local hardware

store to reattach the transfer gear support arm and mounting tab

(ETX125_01.jpg, arrows 1 & 2). I used a type that is good for ABS, PVC,

and CPVC plastic as I figured that the gearbox was made out of ABS. ABS

is commonly use for small plastic parts such as this. Turns out I must

have been right as ETX125_02.jpg shows the gearbox after the initial

repair. These repaired joints are very strong and I was tempted to test

it but I went a step further.

I then used carbon fiber woven cloth (and strand in a couple of areas)

and West System Epoxy to reinforce the support arm and also to reinforce

the gearbox cover screw supports as these had severe cracks in them.

These are numbered 3, 4, & 5 in photo ETX125_01.jpg. I couldn't come up

with a practical solution for reinforcing the mounting tab and if it

fails again I will fashion an L bracket to replace it with. The carbon

fiber I used was from a sample pack that I purchased online through a

company called Fibre Glast. The West System epoxy is commonly used in

marine craft fabrication/repair and is widely available.

ETX125_03.jpg shows the repaired gearbox ready for reinstallation. I

removed the circuit board prior to installation, as it is easier to

install the gearbox without it attached. I had to remove it again later

as I had applied too much Lithium grease, which had spattered about

after initial testing. I tested the scope indoors performing reset,

calibrate motors, and test tracking. After some necessary readjustment,

etc., which I will document in more detail later, I was ready for

outdoors testing.

I went out about 1:30am CST, Sunday morning here in Southern Minnesota.

I was greeted during setup with a couple of meteors from the approaching

Orionid meteor shower. I performed an extensive Train Drives starting

with my 26mm eyepiece, stepping down to 20mm, 15mm, 12.4mm, and 9.7mm. I

then performed an Easy Align.

I am very happy to report that the repairs appear to have been

successful. I spent about 2hr running through the Guided Tour (twice

for several of my favorites) of the Autostar without a hitch or error of

any kind. Tracking was excellent once an object was centered in the

eyepiece. Several times I let the ETX track and walked away for 5 10min

and when I came back the object was still centered in the eyepiece. I

also noticed that the growling, that used to be quite evident before the

failure when the RA drive was tracking, is greatly reduced. I will

perform more extensive tests if the skies stay clear this week, allowing

the scope to track for 15min and longer on a single object.

To sum it up, I think the repairs should hold up well. Only time will

tell. The carbon fiber reinforced areas of the gearbox will be stronger

than how it was initially molded. How the stresses will be transferred

to other areas of the gearbox I don't know. If I had to hazard a guess,

I would think the mounting tab or the support arm loop for the transfer

gear would fail first. The flexing in the support arm that caused the

initial failure is virtually nonexistent with the carbon fiber

reinforcement. I am hoping the repairs will hold at least another year

until I can save up for a new scope, after which I will use the ETX

primarily for terrestrial photography. After pricing the LXD75 mount,

tube rings, Sky Assurance, and other accessories necessary to mount the

ETX tube, I have decided to keep saving until I can purchase a new LXD75

SC8 full setup.

I'm hoping you'll post this on your site. It may also give others who

have had this failure something to think about before giving up on their

ETX 125EC. I have also sent a copy of this to Dr. Clay. Thanks for a

wonderful website. I peruse here from time to time and it has been fun

reading about your journey to Cassiopeia Observatory. Your website has

been an invaluable source of information about how to get the most out

of my ETX. Thank you.

Yours truly,

Paul Torgusen

Subject: Re: ETX 125EC RA Drive Repair ![[NEW!]](../../images/new.gif) Sent: Wednesday, October 28, 2009 20:44:38

From: infoforplt (infoforplt@comcast.net)

We finally had clear skies in Southern Minnesota, USA on Monday,

10/26/09. The humidity was quite high so the best views were within an

arc from the Zenith to about 30 35 degrees towards the horizon all

around the Zenith. The Jupiter First Quarter Moon pairing was nice,

although Jupiter's clouds didn't resolve very well at high power due to

the humidity. My 20yr old daughter and me had a great time for about an

hour and a half. It was a little after 9pm when I got setup and we had

fun checking out the Moon and Jupiter for quite a while and then we

buzzed around the Tour for a bit. Towards the end her boyfriend showed

up and we went back (or should I say forward through the Tour) to the

Moon and we had a lot of fun with different filters. I really like the

Meade 40mm Super Plossl for the Moon. It's also great for the Double

Cluster. Not quite wide enough for the Pleiades though.

About the ETX. I'm really satisfied with the repair. When tracking an

object it was so quiet that I had to put my ear to the base to hear the

RA Drive running. Last year I had grown accustomed to the growling in

the base and thought it was normal. Now I think I know what normal

should sound like. Tracking is excellent. The little skip every so

often along the Azimuth that was also the norm is completely gone. No

motor faults. I can't stress enough the importance of Training Drives

though. I didn't train drives this night as it was just over a week ago

since I had done it. I didn't do an extended tracking test this night

either. On this night, with my daughter there, it was more about the

time together and the fascination for the Universe we both share. We

viewed the Moon for at least 10 minutes twice and it remained centered

in the 40mm just fine. This was only the 2nd night out with the

repaired scope and I'll update again after I get a several hours

straight use. So far this month of October has been the cloudiest here

since the early 1970s and we appear to be on the verge of setting an

all time record. At least for Minnesota known recorded weather data.

Some additional comments about the 2nd remounting of the gearbox

assembly that I think are important. Remember, I had to remove the

gearbox to degrease a little. It took a bit of adjusting until the

gearbox 'settled' into position. This involved getting the support arm

hole adjusted properly along the plastic transfer gear shaft. During

remounting I left out the screws that attach the gearbox housing to the

base purposely until I had the transfer gear secured firmly (but I

didn't totally tighten the cap screw yet) to the worm gear shaft. Then

it took a little careful nudging of the support arm hole, along the

shaft of the transfer gear, until all the mounting holes on the gearbox

settled over their respective holes. I put the base screws in loosely

and then tightened the cap screw on the transfer gear until very tight.

This came loose a few times on me in 2008 and the gear would just spin

on the worm gear shaft. I used some LocTite on the cap screw this time

(I actually had to spread it on the internal threads of the worm gear

shaft) so hopefully that won't happen again, although I'll check it

from time to time. I also lightly scuffed the worm gear shaft with some

80grit automotive sandpaper in a direction parallel to the shaft. This

should reduce the possibility of transfer gear slippage (anybody

remember the advantage of a keyed gear shaft?). Then I double-checked

the support arm to make sure it wasn't binding on the transfer gear

shaft. I don't have a torque wrench so when I tightened the base screws

I brought them down until they made contact with the tabs and then

tightened them just enough so that they didn't flex the plastic tabs.

The rubber supports were just snug. The assembly doesn't rock and, when

the drive slews the support arm doesn't flex that I can notice. I

attribute the lack of support arm flexure to the carbon fiber

reinforcement. Wonderful stuff that carbon fiber.

I hope to have the project documentation published sometime later this

fall.

Clear skies all

Paul Torgusen

Sent: Wednesday, October 28, 2009 20:44:38

From: infoforplt (infoforplt@comcast.net)

We finally had clear skies in Southern Minnesota, USA on Monday,

10/26/09. The humidity was quite high so the best views were within an

arc from the Zenith to about 30 35 degrees towards the horizon all

around the Zenith. The Jupiter First Quarter Moon pairing was nice,

although Jupiter's clouds didn't resolve very well at high power due to

the humidity. My 20yr old daughter and me had a great time for about an

hour and a half. It was a little after 9pm when I got setup and we had

fun checking out the Moon and Jupiter for quite a while and then we

buzzed around the Tour for a bit. Towards the end her boyfriend showed

up and we went back (or should I say forward through the Tour) to the

Moon and we had a lot of fun with different filters. I really like the

Meade 40mm Super Plossl for the Moon. It's also great for the Double

Cluster. Not quite wide enough for the Pleiades though.

About the ETX. I'm really satisfied with the repair. When tracking an

object it was so quiet that I had to put my ear to the base to hear the

RA Drive running. Last year I had grown accustomed to the growling in

the base and thought it was normal. Now I think I know what normal

should sound like. Tracking is excellent. The little skip every so

often along the Azimuth that was also the norm is completely gone. No

motor faults. I can't stress enough the importance of Training Drives

though. I didn't train drives this night as it was just over a week ago

since I had done it. I didn't do an extended tracking test this night

either. On this night, with my daughter there, it was more about the

time together and the fascination for the Universe we both share. We

viewed the Moon for at least 10 minutes twice and it remained centered

in the 40mm just fine. This was only the 2nd night out with the

repaired scope and I'll update again after I get a several hours

straight use. So far this month of October has been the cloudiest here

since the early 1970s and we appear to be on the verge of setting an

all time record. At least for Minnesota known recorded weather data.

Some additional comments about the 2nd remounting of the gearbox

assembly that I think are important. Remember, I had to remove the

gearbox to degrease a little. It took a bit of adjusting until the

gearbox 'settled' into position. This involved getting the support arm

hole adjusted properly along the plastic transfer gear shaft. During

remounting I left out the screws that attach the gearbox housing to the

base purposely until I had the transfer gear secured firmly (but I

didn't totally tighten the cap screw yet) to the worm gear shaft. Then

it took a little careful nudging of the support arm hole, along the

shaft of the transfer gear, until all the mounting holes on the gearbox

settled over their respective holes. I put the base screws in loosely

and then tightened the cap screw on the transfer gear until very tight.

This came loose a few times on me in 2008 and the gear would just spin

on the worm gear shaft. I used some LocTite on the cap screw this time

(I actually had to spread it on the internal threads of the worm gear

shaft) so hopefully that won't happen again, although I'll check it

from time to time. I also lightly scuffed the worm gear shaft with some

80grit automotive sandpaper in a direction parallel to the shaft. This

should reduce the possibility of transfer gear slippage (anybody

remember the advantage of a keyed gear shaft?). Then I double-checked

the support arm to make sure it wasn't binding on the transfer gear

shaft. I don't have a torque wrench so when I tightened the base screws

I brought them down until they made contact with the tabs and then

tightened them just enough so that they didn't flex the plastic tabs.

The rubber supports were just snug. The assembly doesn't rock and, when

the drive slews the support arm doesn't flex that I can notice. I

attribute the lack of support arm flexure to the carbon fiber

reinforcement. Wonderful stuff that carbon fiber.

I hope to have the project documentation published sometime later this

fall.

Clear skies all

Paul Torgusen

|

|