ETX TECHNICAL TIPS

Last updated: 12 March 2000

ETX TECHNICAL TIPS |

From: Spyros Michas (michas@tee.gr)

Dear Mike

Knowing that the tabletop legs are

not practical for field use, I decided to find a tripod solution for my ETX-90.

US made stuff are expensive here, like the Meade field tripod which costs more

than 300$, and there are not many choices around anyway. I thought I could come

up with something cheaper. I also have the do-it-yourself bug of course…

a) Tripod

First, I looked for a reasonably priced suitable tripod. I saw several camera tripods made of aluminum on the market, with prices starting from $80. Luckily, I also found a beautiful old wooden tripod in a friend’s junkyard. This friend is a surveyor, and this tripod was used with his old Wild T-series theodolite. This is a precision optical instrument, and quite heavier than the ETX-90. Therefore, I thought that it should be sturdy enough for the telescope use. The tripod is more than 20 years old, and it was in a pitiful state. However, the metal parts like the connecting top mechanism, and the stop-bolts of the sliding legs, looked OK. I dismantled the tripod; I sanded the metal parts and painted them five thin layers of paint and two hands of varnish. I sanded the wooden legs and painted them three hands of dark varnish. I assembled the tripod, and attached a small metal chain on each leg, connecting them in the middle. This is to prevent the legs from spreading apart when they are used on slippery surfaces. Then, I gave it a thorough test. Everything looked right. The tripod is very sturdy, and capable of safely carrying great weights without the legs sliding. I also realized that the original manufacturer (Wild of Switzerland) used first-grade materials (especially the wood) and great craftsmanship in their work.

|

Cost of tripod: |

$0 |

|

Cost of paint and other necessary

stuff: |

Appr. $35 |

|

Working time: |

10 hrs. |

|

Weight: |

5.2 kgr |

b) Mounting

Next step was to find a mounting

system, able to hold the telescope both in Alt-Az and Polar-aligned positions.

I was lucky to have a Mechanical Engineer friend that helped me to design

something efficient, simple and at a reasonable cost. We gave it a lot of

thought and finally decided to build a simple mechanism with two holding parts

and a pitch axis screw and bolt, plus a base to put on the tripod and a top

unit to bolt the telescope onto. We also applied a simple leveling mechanism

with three screws, similar to those used on surveying equipment, but much

simpler. We chose aluminum for our material. I gave my friend George my final

designs, and he went on to build the thing. It took around 4 working hours on

the lathe and 6 more on other finishing equipment. Since he is a friend, he

didn’t charge anything, but this should mean a small fortune if you have to pay

the machine shop! We assembled the

mechanism, attached and adjusted a leveling bubble, and screwed the whole set

on the tripod. I also attached a small plastic protractor and made some

markings to be used on the polar alignment procedure. With a little practice, I

managed to be able to easily level and polar-align the scope. The first flaw we

found was that the bolt of the pitch axis screw required a lot of strength to

be safely fastened. This was because of the low friction between the two

aluminum surfaces. I made it a little better by putting a small piece of strong

tape with a rough surface between them. At last, it was ready! It has proved to

work fine till now. The leveling works great, and is very precise, probably

more than necessary. The telescope performed fine at a polar-aligned setup. The

weight of the mounting system is over 2kg, quite heavy, but works in favor of

the stability of the system. The system won’t budge easily, and is hard to tip

over, even with the telescope at 38° (Athens, Greece). It is even better

at an Altazimuth positioning. I’m quite happy with my work, and have no major

complain after a total of about 20 hours of use. I have not tried any special

equipment on it yet.

|

Cost of aluminum: |

$20 |

|

Cost of screws, protractor and

other necessary stuff: |

Appr. $30 |

|

Working time: |

10 hrs to

build, but a lot more time to think of the design and produce the plans |

|

Working cost: |

$0 |

|

Weight: |

2.3 kgr |

c) Conclusions

I had great fun trying to design and

build my custom field tripod. There is nothing that can replace the pleasure of

making stuff and having good laughs with friends over the process. I also

believe that the final result is simple, practical and aesthetically pleasing.

Therefore I can say that I am very happy with my field tripod. The only

drawback is its weight, and the not so efficient pitch screw and bolt. The cost

seems very low, but you must bear in mind that I had for free what should be

the most expensive part of the project, which is the working hours of the

mechanic. A wooden tripod could be expensive, but a plain aluminum tripod costs

a lot less. I would recommend my design as a cheap solution only to one that

can find access to cheap heavy machinery tools. Otherwise, it could cost as

much as something available on the market.

d) Photographs

Pict. 1: The tripod, the mounting and my ETX carrying bag.

Pict. 2: The ETX on the tripod at

Altazimuth position. You can see the three leveling screws, the protractor, the

pitch screw, and the top of the tripod.

Pict. 3: The ETX on the tripod at a

polar-aligned position.

Pict. 4: The ETX on the tripod at a

polar-aligned position. Note the screw of tripod connecting the mounting

mechanism. You can also see the bolt of the pitch screw and one of the two

¼” screws attaching the telescope to the mechanism.

Pict. 5: The top of the tripod. Note

the screw. Its threading is of a weird size, and carving the aluminum base of

the mounting was a challenging task

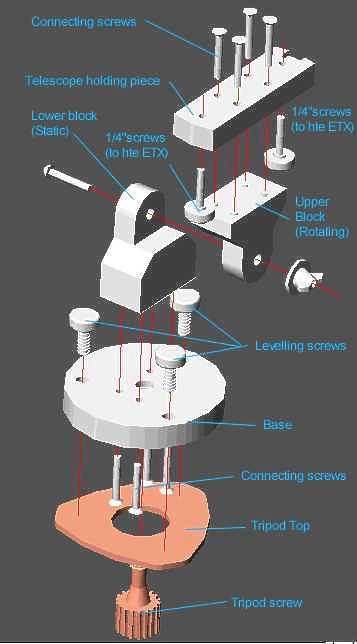

Pict. 6: Here are the parts of the mounting system. You can see the base, with the three leveling screws and the bubble. You can also see the screws connecting the base part with the lower part of the pitching mechanism and the protractor. On the top part, note the 4 screws connecting the mounting base to the upper part of the pitch axis. Note the little carving on one end, to host the ETX’s rubber pad under its base. More details to be found in the drawing.

Pict. 7: This is a bitmap of the 3D model of the system in exploded view.

Pict. 8: This is

a bitmap of the plans

e) Digital

drawings

Attached (Right-click or option-click to download 148K file) you will find the drawings of my work. The format is Autocad2000, and it is the vector version of picture 8. I have also included an animation of the exploded model. Click to begin movie. It will appear in a new window.

Note: One could notice minor differences

between the final drafting and the final output (Lucky as I was to have great

mechanics work for me, they took the initiative to make some last minute

“enhancements”). The differences are:

q

The

lower block has a different base and the upper block final shape is a little

altered.

q

The

way the lower block is attached to the base is different.

q

I

haven’t cut yet the telescope holding ¼” screws. Instead I used two

plain ¼” screws of 30mm height. The screws of the drawing are on their

way.

These changes are not important and do not

affect the efficiency of the system at all. After all, these drawings are

mainly useful as an idea of the concept.

f) Credits

Many thanks to my friend George

Vettas and his father Stelios, for their invaluable help. They provided their

machinery workshop in their factory in Athens. They are worthy engineers and

great artists! Thanks to my friend Costas Thanos for lending his digital

camera.

You can put any of this on-line if

you want to. Since English is not my mother language, you may find spelling or

grammatical errors. Please correct them. I also hope that I am clear enough

with my engineering terms!

Thank you for your time, I wish to

you and your web-page visitors clear skies.

Spyros Michas

michas@tee.gr

Athens, Greece

Return to the top of this page.

Go back to the Tech Tips page.

Go back to the ETX Home Page.